What is the formula for calculating EOQ?

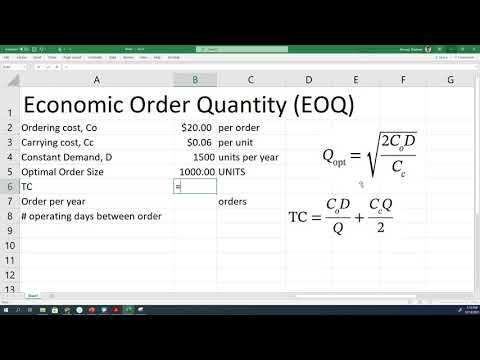

Also referred to as ‘optimum lot size,’ the economic order quantity, or EOQ, is a calculation designed to find the optimal order quantity for businesses to minimize logistics costs, warehousing space, stockouts, and overstock costs. The formula is: EOQ = square root of: [2(setup costs)(demand rate)] / holding costs.

What is EOQ explain with example?

Example of Economic Order Quantity The shop sells 1,000 shirts each year. It costs the company $5 per year to hold a single shirt in inventory, and the fixed cost to place an order is $2. The EOQ formula is the square root of (2 x 1,000 shirts x $2 order cost) / ($5 holding cost), or 28.3 with rounding.

Why is EOQ calculated?

Why do you need the Economic Order Quantity formula? The Economic Order Quantity (EOQ) formula helps to avoid these mis-stocking situations. It calculates the ideal number of units you should order, such that the cost involved is minimal and number of units is optimal.

What is EOQ and its formula in management accounting?

The EOQ formula is as follows. EOQ = Square root of [(2 x demand x ordering cost) / carrying cost] Demand. The demand remains constant according to the assumptions made by EOQ. The demand is how much inventory is used per year or how many units are sold per year.

How do you solve EOQ problems?

How do you calculate total cost and EOQ?

The total cost of inventory is the sum of the purchase, ordering and holding costs. As a formula: TC = PC + OC + HC, where TC is the Total Cost; PC is Purchase Cost; OC is Ordering Cost; and HC is Holding Cost.

What is EOQ method?

Economic order quantity (EOQ) is a calculation companies perform that represents their ideal order size, allowing them to meet demand without overspending. Inventory managers calculate EOQ to minimize holding costs and excess inventory.

What is the formula of reorder level?

To calculate the reorder level, multiply the average daily usage rate by the lead time in days for an inventory item.

What is order cost in EOQ?

What are Ordering Costs? Ordering costs are the expenses incurred to create and process an order to a supplier. These costs are included in the determination of the economic order quantity for an inventory item.

How do I calculate inventory?

The basic formula for calculating ending inventory is: Beginning inventory + net purchases – COGS = ending inventory. Your beginning inventory is the last period’s ending inventory. The net purchases are the items you’ve bought and added to your inventory count.

What is the formula for total cost?

The formula to calculate total cost is the following: TC (total cost) = TFC (total fixed cost) + TVC (total variable cost).